Business

Aerogas Processors Ltd. (APL), a privately held company that operates a plant producing and supplying an industry standard commercial and cosmetic grade hydrocarbon propellant for use in the Aerosol Filling Industry; deodorized butane for blowing polystyrene products; and various LPG fuel blends. The existence of an established and expanding natural gas based petrochemical industrial sector ensures a ready supply of feedstock and makes Trinidad & Tobago an ideal location for this enterprise.

APL procures its feedstock – propane and butane — from Phoenix Park Gas Processors Limited (PPGPL), the sole processor of high quality liquid petroleum gases, in Trinidad and Tobago. Propane and butane are supplied to APL via an interconnecting pipeline between the two plants.

Location

APL’s plant is located at North Sea Drive, Point Lisas Industrial Estate, on a 1,418 m2 site leased for thirty (30) years from the Point Lisas Industrial Development Company. The site is large enough to accommodate foreseeable future expansion.

Plant

The plant has an initial design production capacity of 10,000,000 gallons per year of blended hydrocarbon aerosol propellant. The layout and other considerations necessary to increase to supply to 20,000,000 gallons per year have already been factored into the current plant. The facilities will also allow for bulk loading of product.

Safety

The codes of the US National Fire and Protection Agency and the American Petroleum Institute, and the UK Health and Safety guideline were applied in the design and construction of the plant. Following the completion of the Environmental Assessment and Risk Analysis of the facility by local and international consultant’s approvals for operation were granted.

Product

APL employs state of the art blending equipment to produce:

A. Aerosol propellants with vapor pressures suitable for personal care, household, automotive, industrial and agricultural aerosol spray products;

B. Deodorized butane as a Blowing agent in the manufacture of polystyrene and of Styrofoam products; and

C. Different LPG fuel blends that are utilized in the commercial and domestic markets in each territory.

Method of Delivery

APL delivers all of the above products by IMO-5 ISO tankers (capacity: 6000 USG) on commercial shipping lines. APL owns its own fleet of IMO-5 ISO tankers as well as will accept the use of customer owned IMO-5 ISO Tankers.

Clients

Over the past 22 years, APL has serviced the entire Caribbean Basin and has exported millions of gallons of high quality products to be used in several markets within the Central and South America region, Caricom countries and the USA. Additionally, we also supply product to various local industries.

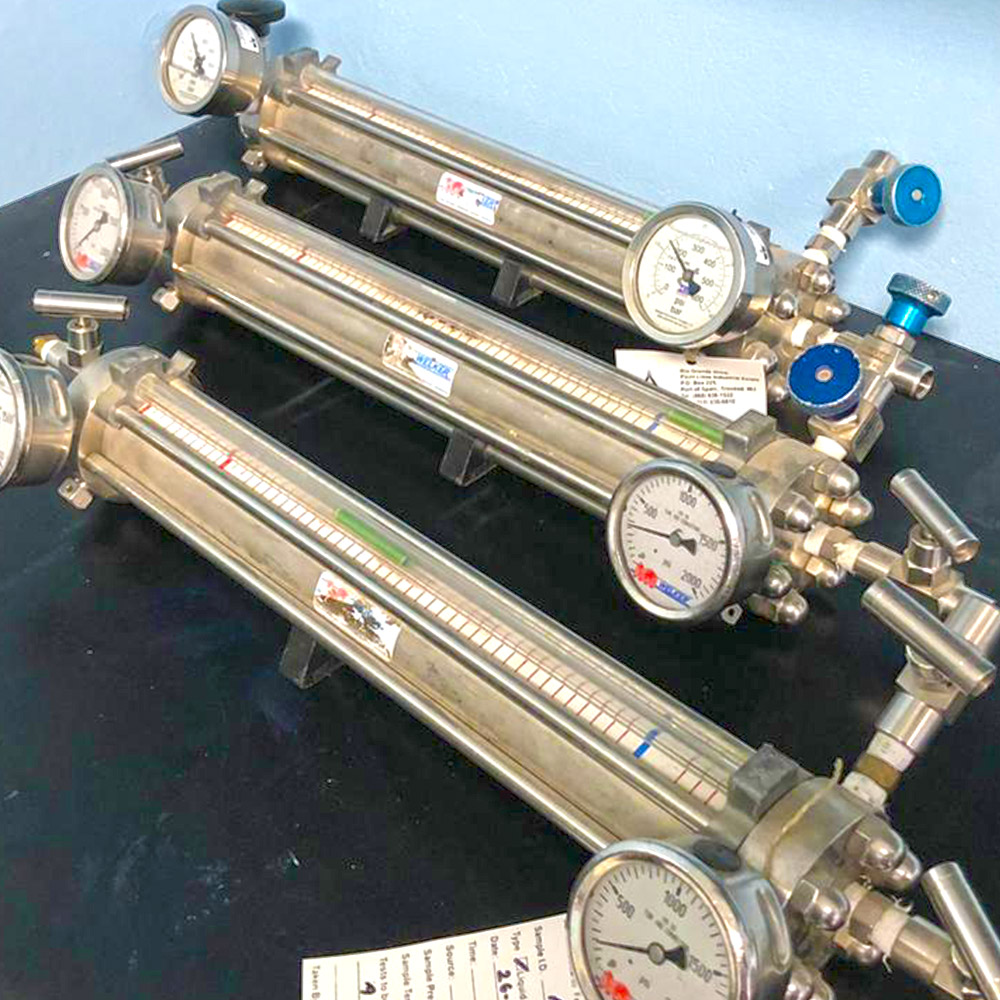

Quality Control

On-site laboratory personnel monitor both the process and product deliverable quality. Samples are taken at various points throughout the process for gas chromatograph analysis, determinations of vapour pressure and temperature values, and moisture and sulphur concentrations. The end result is the consistent delivery of a high quality standard product to meet customer specifications’.

Management

- Joseph Naime – Chairman

- George Naime – Managing Director

- Anthony Rahael – Sales Director

- Victor Bryan – General Manager

- Jacob Wihby – Asst. General Manager

- Belkis López Gómez – Sales / Marketing Officer

- Fermeda Mohammed – Finance Controller

Capacity

APL produces different blends of high quality aerosol propellants and LPG fuels. APL’s plant was initially designed with a capacity of 10 million gallons of product per year, and has state of the art blending equipment used to provide the vapor pressures of the propellants required for personal care, household, automotive, industrial and agricultural aerosol spray products.

Quality

The Propane and Butane feed stocks conform to internationally accepted specifications of the Gas Processor Association (GPA,) Standard 2140-86. The methodology used for testing the products to ensure conformance with the customers’ requirements and those are listed in the American Society for Testing Materials (ASTM).